TCCV2 - Textile Competence Center Vorarlberg 2

Programme: COMET – Competence Centers for Excellent Technologies

Programme line: COMET-Project

Type of project: Multi-firm project 3.1 replacing oil-based fibres by natural and bio-based fibres

Partially hydrophobic hybrid fibres are developed by single fibre coating

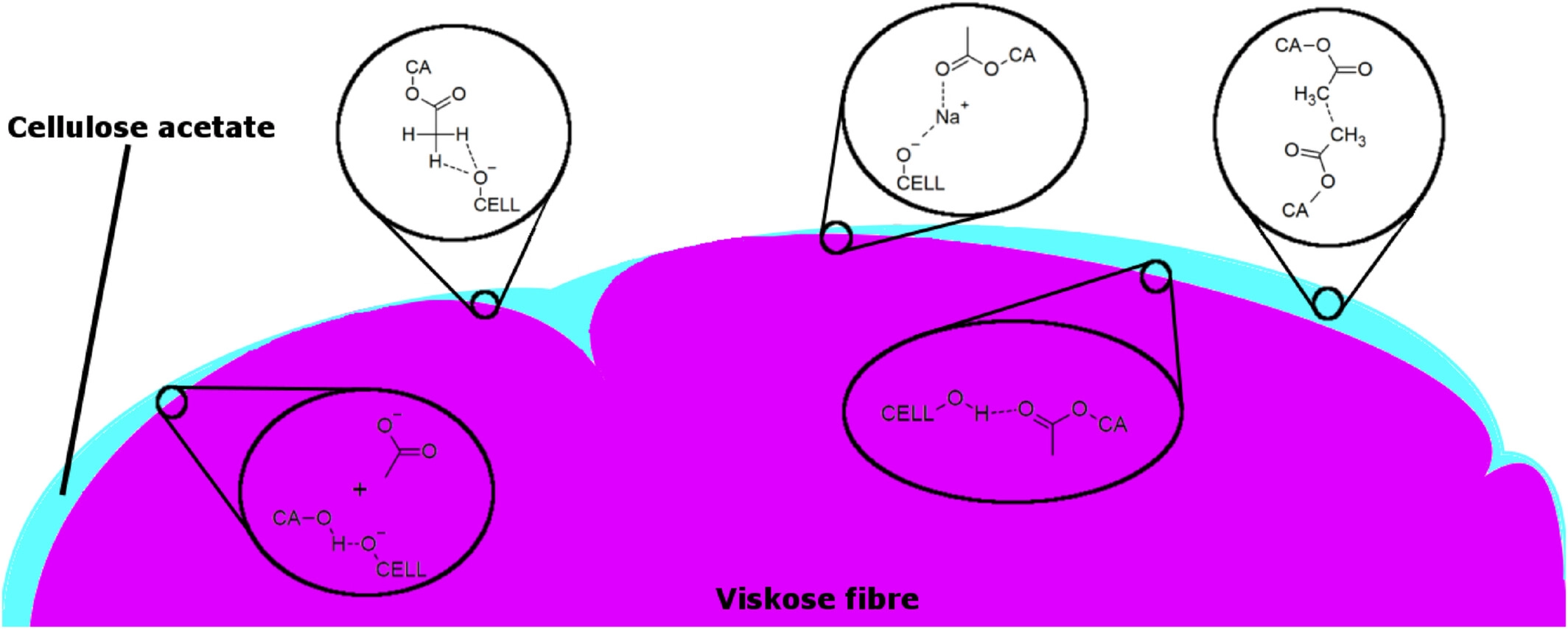

Cellulose is a multifaceted material. Pure or by chemical modification several different materials can be produced. Aside from plain cellulose materials, which are extensively used in apparel and paper industry, cellulose acetate (CA) is a widely used cellulose-based material. It serves as material for garment, cigarette filters and high impact applications, among others. The latter is chemically modified by the esterification of the hydroxyl groups of cellulose to acetate groups. While the cellulose backbone is equivalent in both cases, aside from a degree of polymerization reduction while the modification, the different functional groups, hydroxyl and acetate, affect several material properties. Cellulose is rather hydrophilic, is spun into different fibre types and can be dissolved in several solvents, including sodium hydroxide water systems. This hydrophilicity bases on the number of hydroxylic groups on the polymer. CA is more hydrophobic than pure cellulose materials, and is considered thermoplastic, requiring the use of plasticizer as restrictions of the degree of substitution. Due to the acetate side groups, the moisture regain is reported only 6.5% by mass for cellulose diacetate with a degree of substitution (DS) of 2.5, compared to specific types of cellulose, for example, 13%–14% for viscose fibres.

To develop and invest towards bio-based and biodegradable materials, we follow an alternative approach. We coat viscose fibres with partially hydrophobic cellulose acetate. This is an approach to combine the tensile properties and tenacity of viscose with an additional hydrophobic coating. We accordingly hypothesise that by a selective coating of cellulose fibres using cellulose acetate, the moisture regain and water uptake of the cellulosic fibre can be reduced. We aim to understand if this approach is realizable, and if the interfacial adhesion of viscose and cellulose acetate is sufficient to withstand mechanical stress.

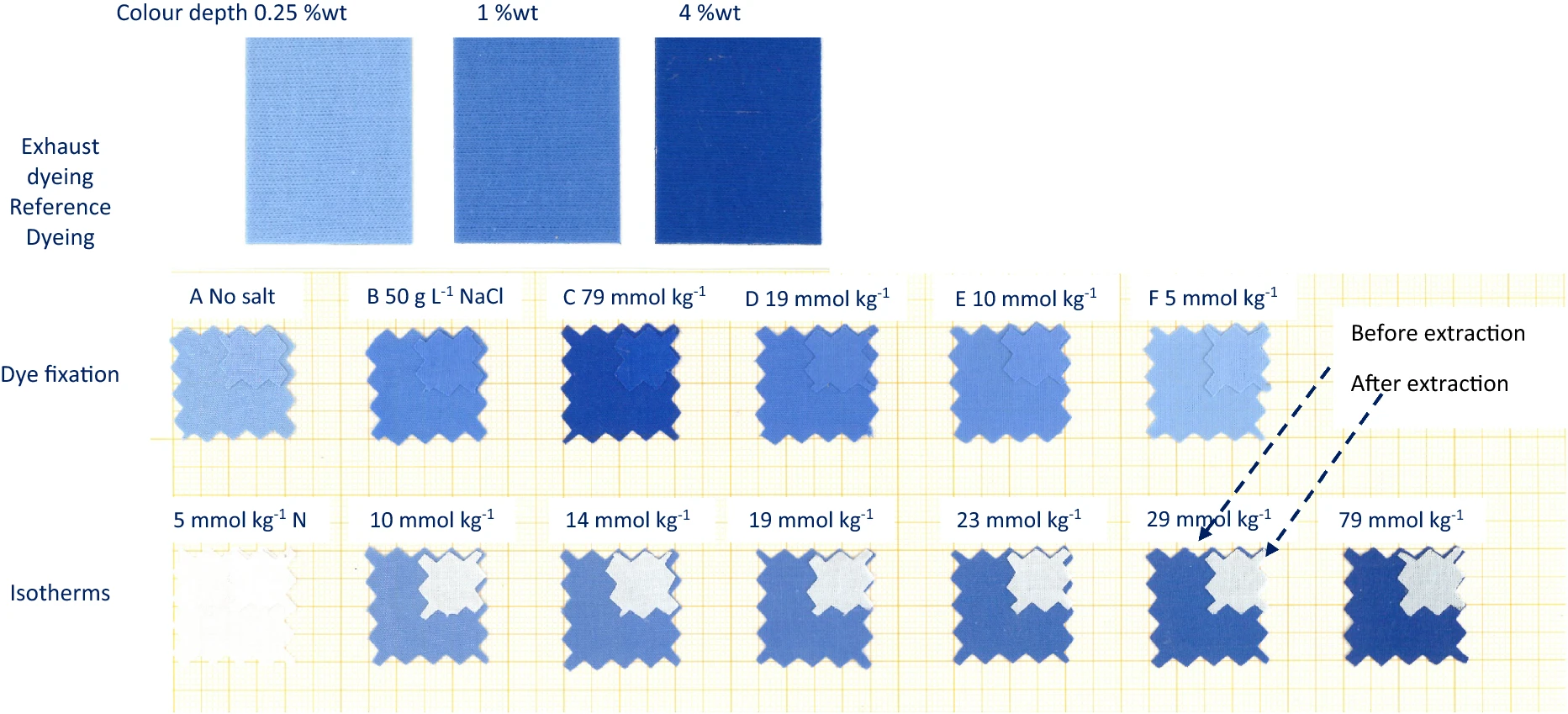

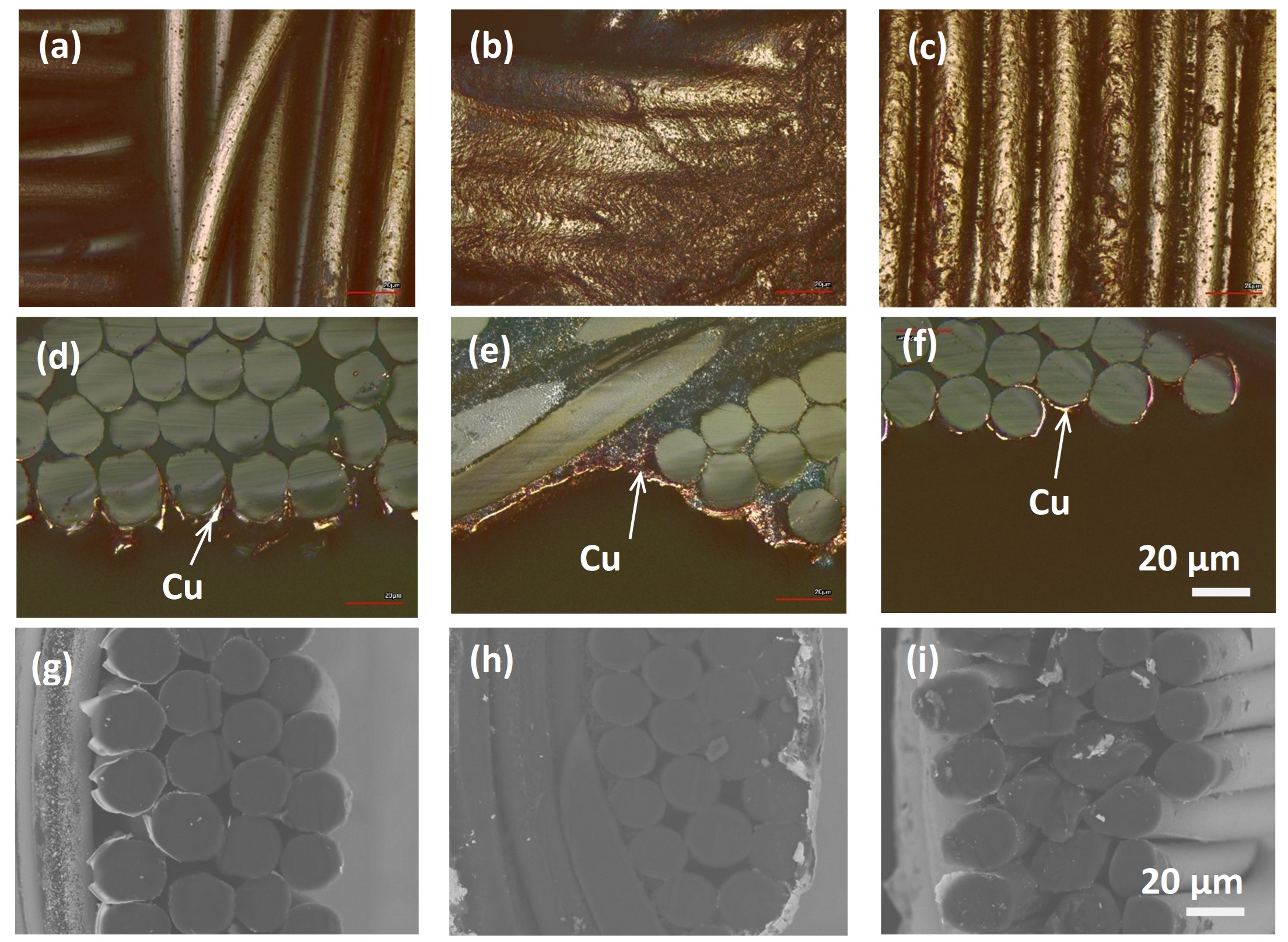

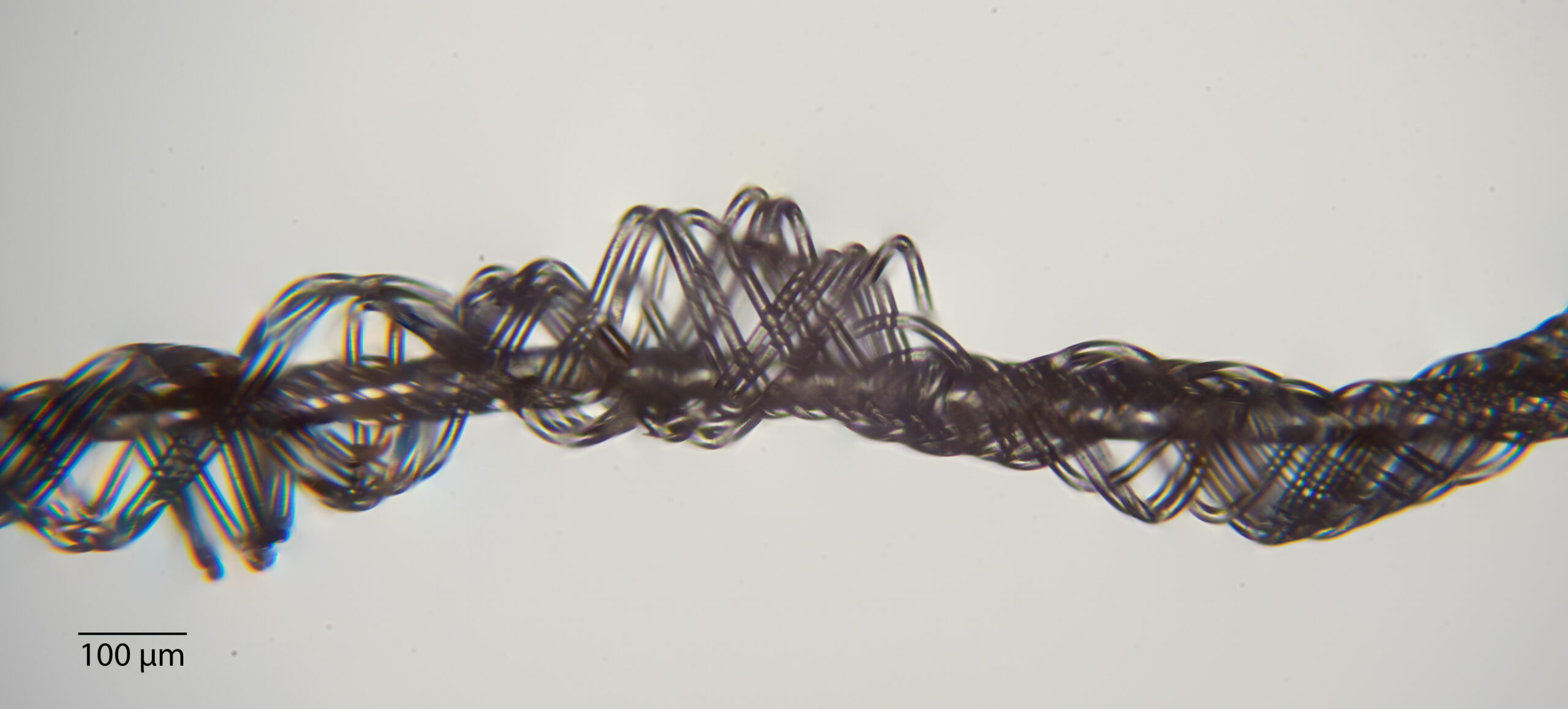

The focus of this work was to investigate the cellulose acetate (CA)–viscose (CV) interface in an all-cellulosic compound and to evaluate the feasibility of hydrophobic CA-coatings on viscose fibres. Mechanical strengths of cellulose foil-CA compounds were investigated by recording stress-to-strain curves. For equivalent strain, composites generate higher stress than pure CA samples. For the CA coating on CV fibres, fibres were pretreated in 2.5% by mass sodium hydroxide solution and drawn through a solution of 2%, 4%, 6%, 8%, and 10% by mass in acetone dissolved CA. Properties of coated fibres were investigated with LSM microscopy, ATR-FTIR, DVS, and by determining the fibre titer and tenacity. A decrease in fibre tenacity and vapour sorption is associated with a change of the fibre titer due to the increasing shares of CA. Therefore, the hypothesis of a hydrophobically coated CV fibre, via the described process, is mostly rejected, although double-coatings with CA seem to reduce condensation of water in internal fibre structures at high humidity.

Publication:

Wurm, F. Netzer, U. Schäffner, J. Leukel, J. Schweiß,

T. Pham, T. Bechtold, Single fiber coating of viscose filaments with cellulose acetate for partially hydrophobic hybrid fibers, J. Appl. Polym. Sci. (2023).

https://doi.org/10.1002/app.53890

Project coordination (Story)

Univ.-Prof. Dr. Tung Pham

Research Institute of Textile Chemistry

and Textile Physics

Universität Innsbruck

T +43 5572 28533

textilchemie@uibk.ac.at

www.uibk.ac.at/textilchemie

COMET-Project TCCV2

Research Institute of Textile Chemistry

and Textile Physics,

Universität Innsbruck

Hoechsterstrasse 73, A-6850 Dornbirn

T +43 5572 28533

textilchemie@uibk.ac.at

www.tccv.eu

This success story was provided by the consortium leader and by the mentioned project partners for the purpose of being published on the FFG website. TCCV is a COMET Project within the COMET – Competence Centers for Excellent Technologies Programme and funded by BMK, BMDW and the state of Vorarlberg. The COMET Programme is managed by FFG. Further information on COMET: www.ffg.at/comet

Austrian Research Promotion Agency

Sensengasse 1, A-1090 Vienna

P +43(0)57755-0

office@ffg.at

www.ffg.at