TCCV2 - Textile Competence Center Vorarlberg 2

Programme: COMET – Competence Centers for Excellent Technologies

Programme line: COMET-Project

Type of project: Strategic project 1.1 Interface interaction in hybrid systems

Combination of 3D carbon structure and oxidic activation for redox flow batteries

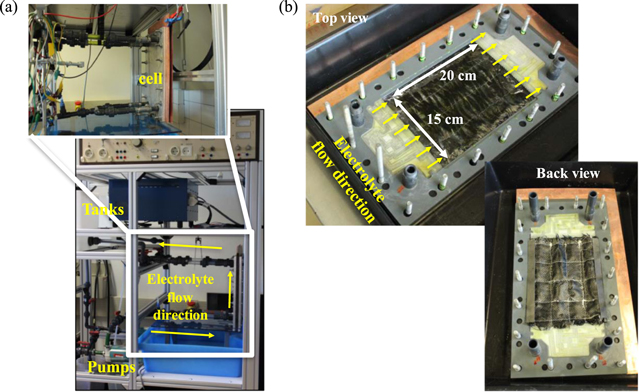

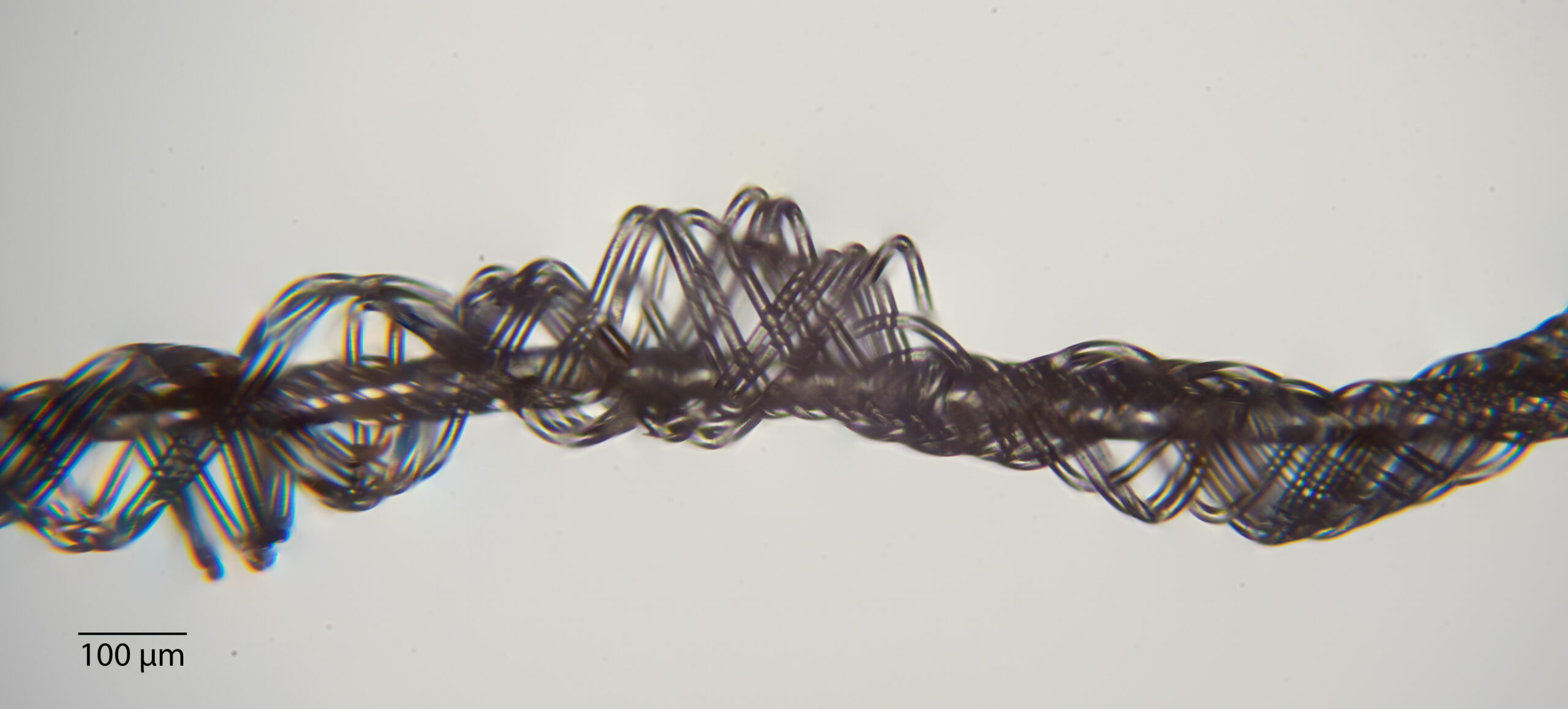

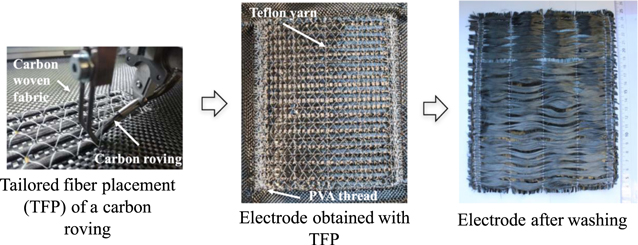

The potential of embroidery as tailored fibre placement (TFP) of continuous carbon filaments was investigated by UIBK to create high-performance electrodes for redox flow batteries. A redox flow cell was specially designed and developed to host large embroidered electrodes with a geometric area of 300 cm2. The process for the electrode preparation is illustrated as depicted in the picture below.

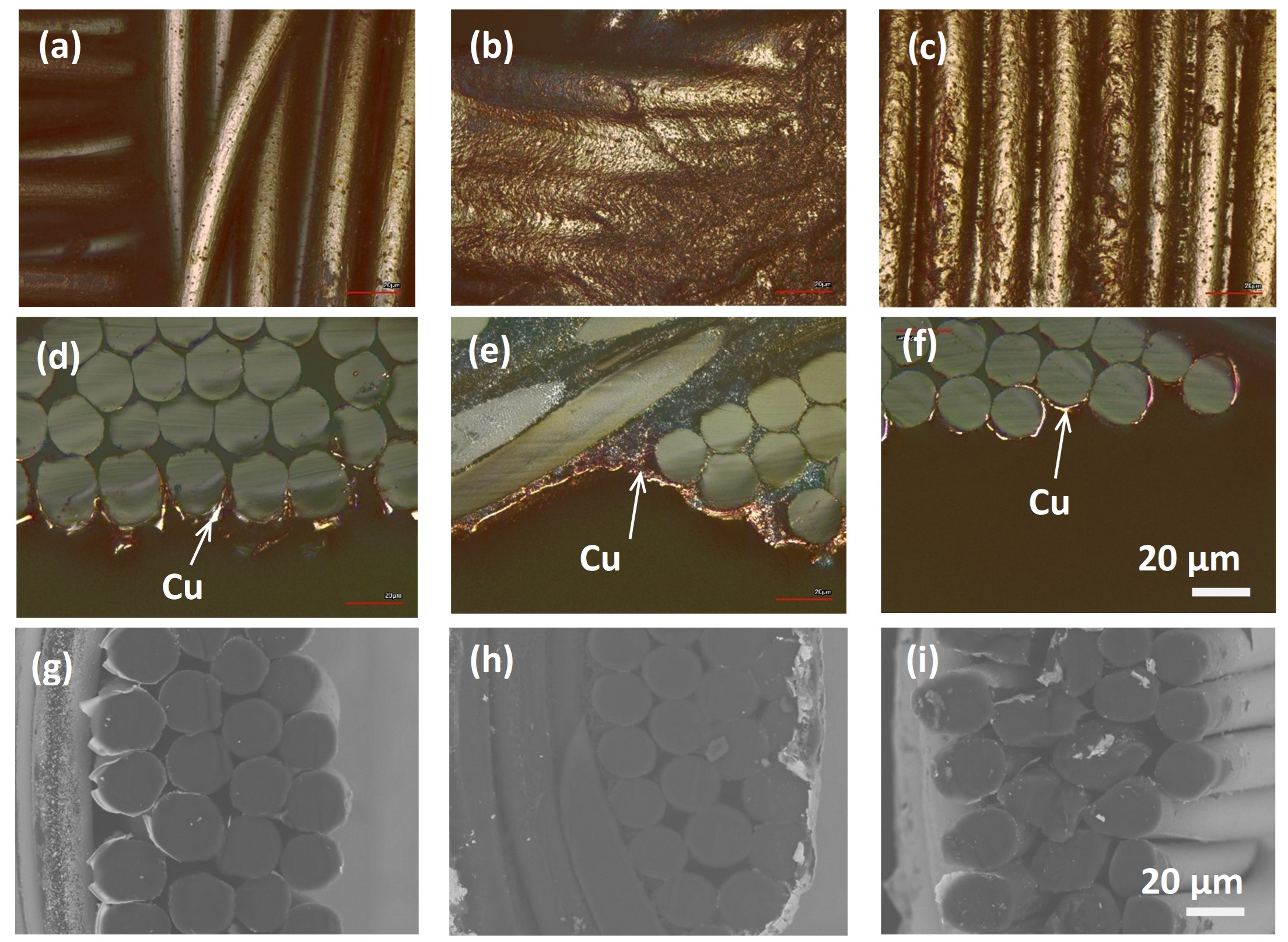

Electrochemical impedance spectroscopy (EIS) measurements were performed in 50% state-of-charge (SOC) ferro/ferricyanide redox couple as probe electrolyte to identify the contribution of the different resistance losses (ohmic, charge-transfer and mass-transfer losses). Different electrode designs were constructed to investigate the effect of the number of layers (i.e. number of carbon filaments, thickness) on the different resistance contributions. The results were compared to conventional felt electrodes.

In contrast to conventional felt electrodes, which require compression to achieve the electrical contact to the current collectors, the electrical contact of the embroidered electrodes was achieved through side contacting. Electrode compression minimizes the ohmic losses, but leads to high pressure drops, poor hydraulic permeability of the electrolyte, and a decrease in the electrode porosity. The ohmic cell resistances obtained with the embroidered electrodes were comparable to conventional felt electrodes, independently of the volume occupied by the electrodes in the electrode compartment. The outcomes open new routes for electrical contacting without the need of electrode compression.

By using embroidered electrodes, the pressure drop through the cell was lower as compared to that obtained with the felts. The reduced hydraulic resistance was attributed to the parallel orientation of the carbon filaments with respect to the electrolyte flow. By reducing the pressure drop, the energy consumed by the pump is also reduced, which yields greater battery system efficiency.

With regard to the environmental friendliness of the entire energy storage systems, a non-toxic, pH-neutral, iron-coordination compounds were developed by UIBK as redox carriers in both negative and positive electrolytes for redox flow batteries.

Publication

Schröder, N. Aguiló-Aguayo, D. Obendorf, T. Bechtold, Near to neutral pH all-iron redox flow battery based on environmentally compatible coordination compounds, Electrochim. Acta. 430 (2022) 141042.

https://doi.org/10.1016/j.electacta.2022.141042

Project coordination (Story)

Univ.-Prof. Dr. Tung Pham

Research Institute of Textile Chemistry

and Textile Physics

Universität Innsbruck

T +43 5572 28533

textilchemie@uibk.ac.at

www.uibk.ac.at/textilchemie

COMET-Project TCCV2

Research Institute of Textile Chemistry

and Textile Physics,

Universität Innsbruck

Hoechsterstrasse 73, A-6850 Dornbirn

T +43 5572 28533

textilchemie@uibk.ac.at

www.tccv.eu

This success story was provided by the consortium leader and by the mentioned project partners for the purpose of being published on the FFG website. TCCV is a COMET Project within the COMET – Competence Centers for Excellent Technologies Programme and funded by BMK, BMDW and the state of Vorarlberg. The COMET Programme is managed by FFG. Further information on COMET: www.ffg.at/comet

Austrian Research Promotion Agency

Sensengasse 1, A-1090 Vienna

P +43(0)57755-0

office@ffg.at

www.ffg.at