TCCV2 - Textile Competence Center Vorarlberg 2

Programme: COMET – Competence Centers for Excellent Technologies

Programme line: COMET-Project

Type of project: Strategic project 1.1

Interface and Hybrids

Multi-firm project 2.2 Flexible circuits, sensors and e-textiles

The adhesion of metal/textile interface is enhanced by complexation-mediated fibre surface modification

With an expected market size of $ 5.55 billion dollars in 2025 and a compound annual growth rate of 30.4% from 2019 to 2025, the electronic textile sector is considered an emerging field with very high potential in several applications, e.g. health care for medical monitoring of physiological signals, in sports for guided training and rehabilitation of athletes, or in personal protection equipment.

A key element for the development of electronic textiles is the formation of conductive tracks and circuits on fibres and textile structures. For achieving a reliable conductive structure during the entire usage lifetime, the modification of the substrate is often indispensable to improve the adhesion between the textile substrate the conductive structure.

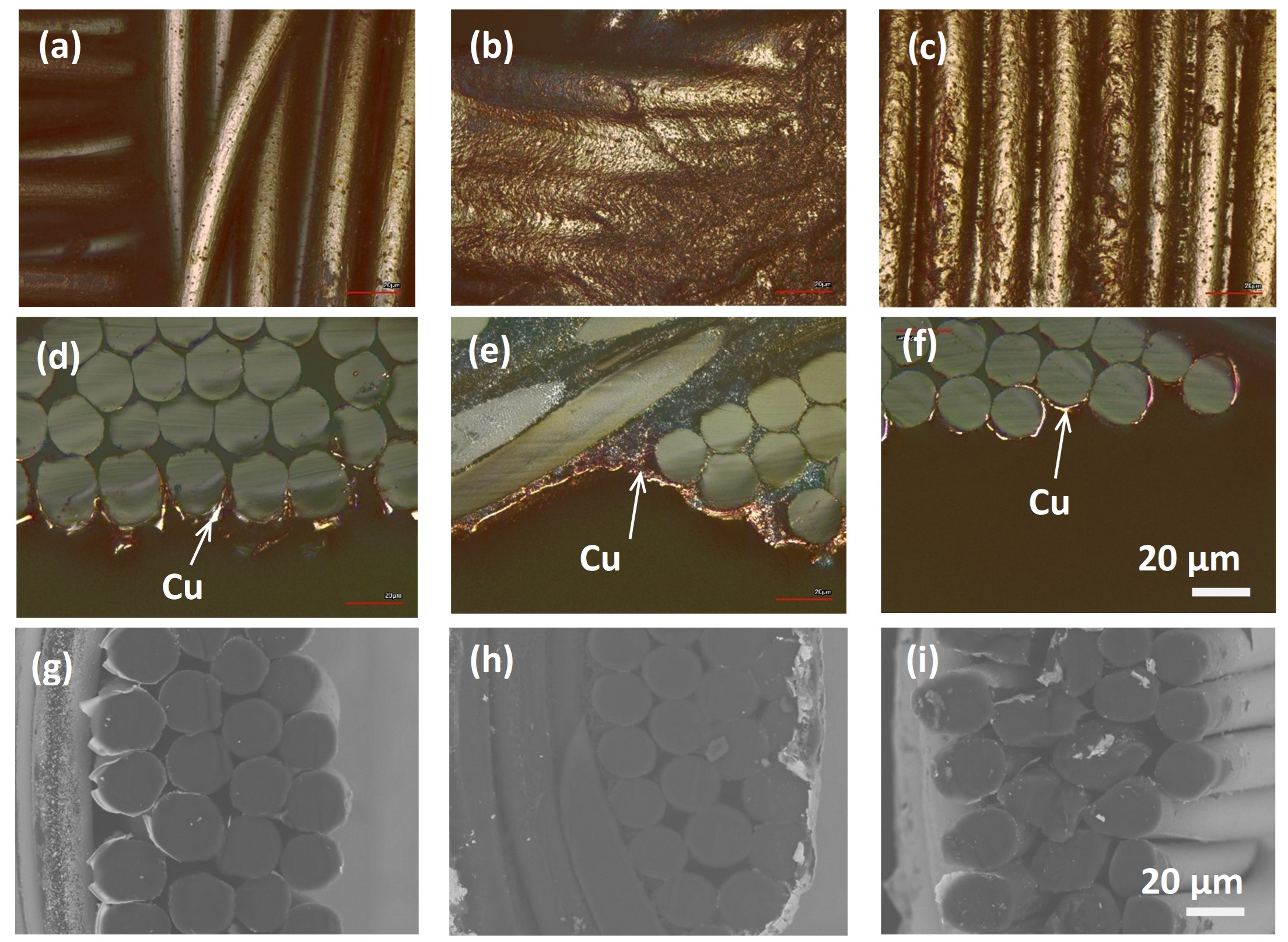

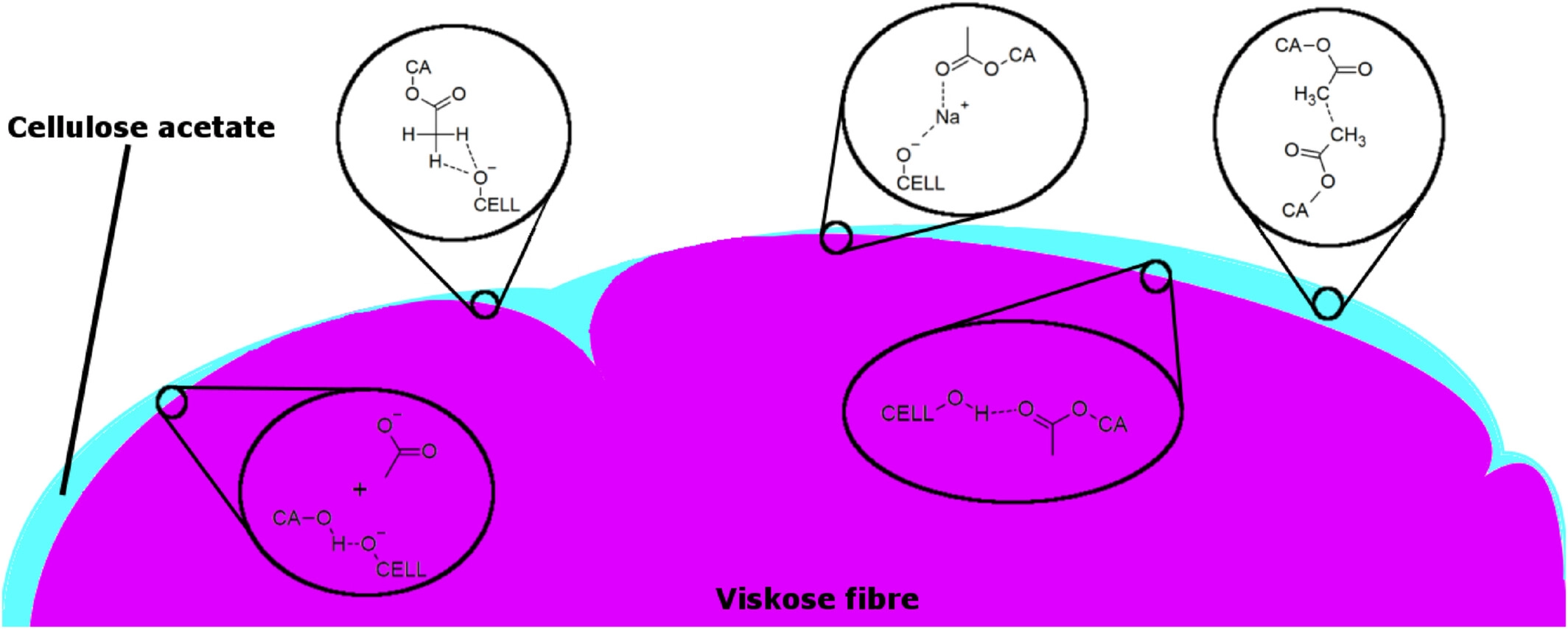

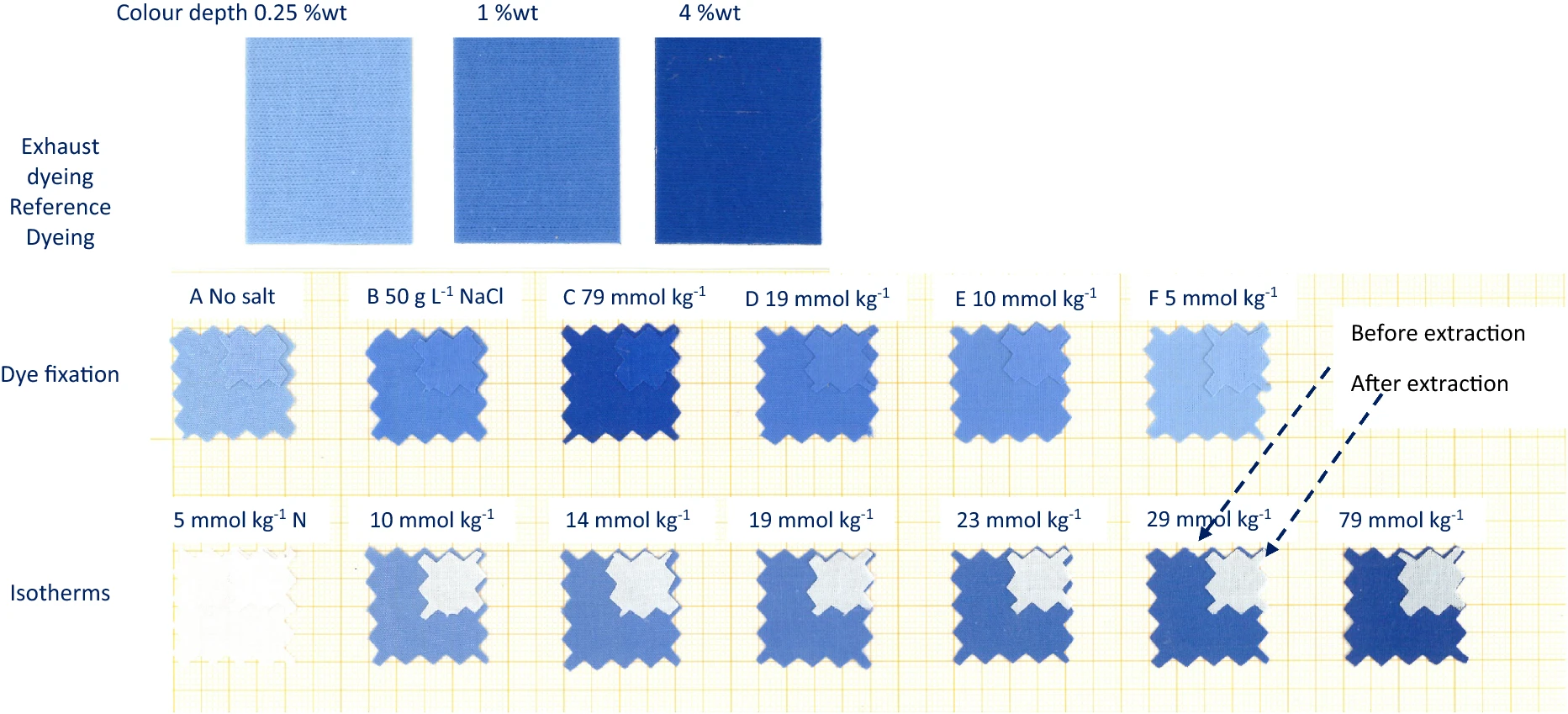

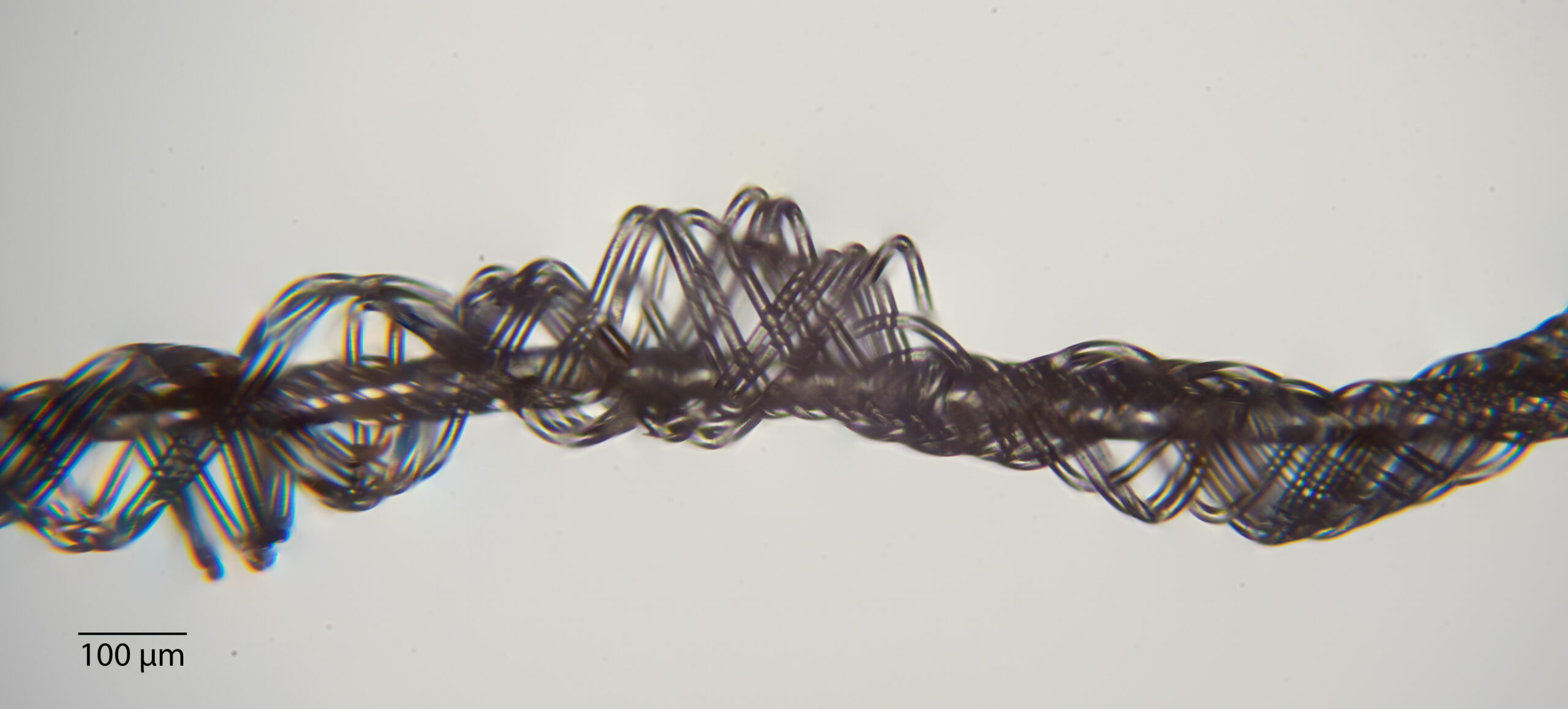

In this work, we have further developed the complexation mediated surface treatment technique using CaCl2/EtOH/H2O solution (CEW) for the modification of PA66 fibre and fabric which were subsequently coated with copper by currentless deposition. As a result of the treatment, a porous shell layer was formed at the fibre surface.

Apart from the topographical change of the fibre/fabric surface, there was no further significant influence on other polymer parameters. Compared to untreated and state- of-the-art plasma modified samples, CEW modification resulted in the highest abrasion resistance as a result of the better migration of metal ions into the thin porous shell structure, allowing stronger anchoring of the metal layer to the substrate. After 10 000 abrasion cycles, 90% copper still remained on CEW modified coated fabric, exhibiting very low resistance.

Thus, CEW complexation mediated modification technique is proven to be simple to implement, but efficient to enhance the polymer/metal interface in copper coated PA66 fibre.

Publication:

Gleissner, C. Biermaier, T. Bechtold, T. Pham, Complexation-mediated surface modification of polyamide-66 textile to enhance electroless copper deposition, Mater. Chem. Phys. 288 (2022) 126383.

https://doi.org/10.1016/j.matchemphys.2022.126383

Project coordination (Story)

Univ.-Prof. Dr. Tung Pham

Research Institute of Textile Chemistry

and Textile Physics

Universität Innsbruck

T +43 5572 28533

textilchemie@uibk.ac.at

www.uibk.ac.at/textilchemie

COMET-Project TCCV2

Research Institute of Textile Chemistry

and Textile Physics,

Universität Innsbruck

Hoechsterstrasse 73, A-6850 Dornbirn

T +43 5572 28533

textilchemie@uibk.ac.at

www.tccv.eu

This success story was provided by the consortium leader and by the mentioned project partners for the purpose of being published on the FFG website. TCCV is a COMET Project within the COMET – Competence Centers for Excellent Technologies Programme and funded by BMK, BMDW and the state of Vorarlberg. The COMET Programme is managed by FFG. Further information on COMET: www.ffg.at/comet

Austrian Research Promotion Agency

Sensengasse 1, A-1090 Vienna

P +43(0)57755-0

office@ffg.at

www.ffg.at