ASSESMENT OF NEW GARMENT AND MATERIAL DESIGN FOR BETTER AERODYNAMIC PROPERTIES

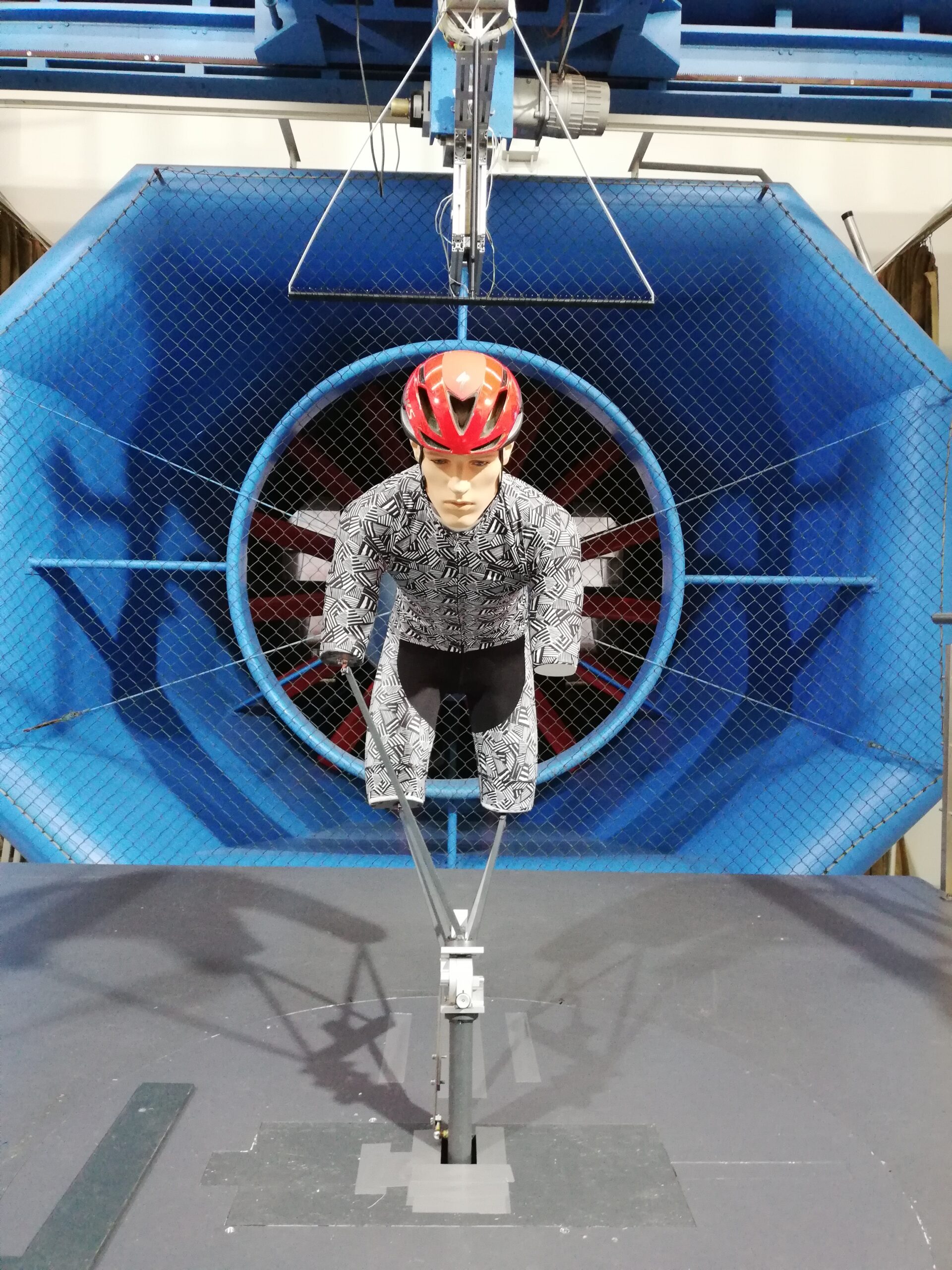

Improvement of aerodynamic design for race suites requires a rather complex setup. Based on results made in the experimental small scale wind tunnel setup at the tccv in Dornbirn, full scale wind tunnel experiments were organized to investigate the design and material concepts in full scale dimensions.

Wind tunnel experiments

A full scale testing in an external wind tunnel was undertaken at GST wind tunnel in Immenstaad.

Tests: Cycling test with a mannequin and Langlauf test with athlete in 2 positions

In both test cases, measurements were made with forces measured via the underfloor balance. The cycling clothing tests were made with a mannequin at 45km/h (12.5m/s) with some configurations repeated at 30km/h (8.3m/s) to assess speed related effects. The purpose of this ‘multi-sweep’ dynamic yaw test sequence procedure is to average out any effect of hysteresis.

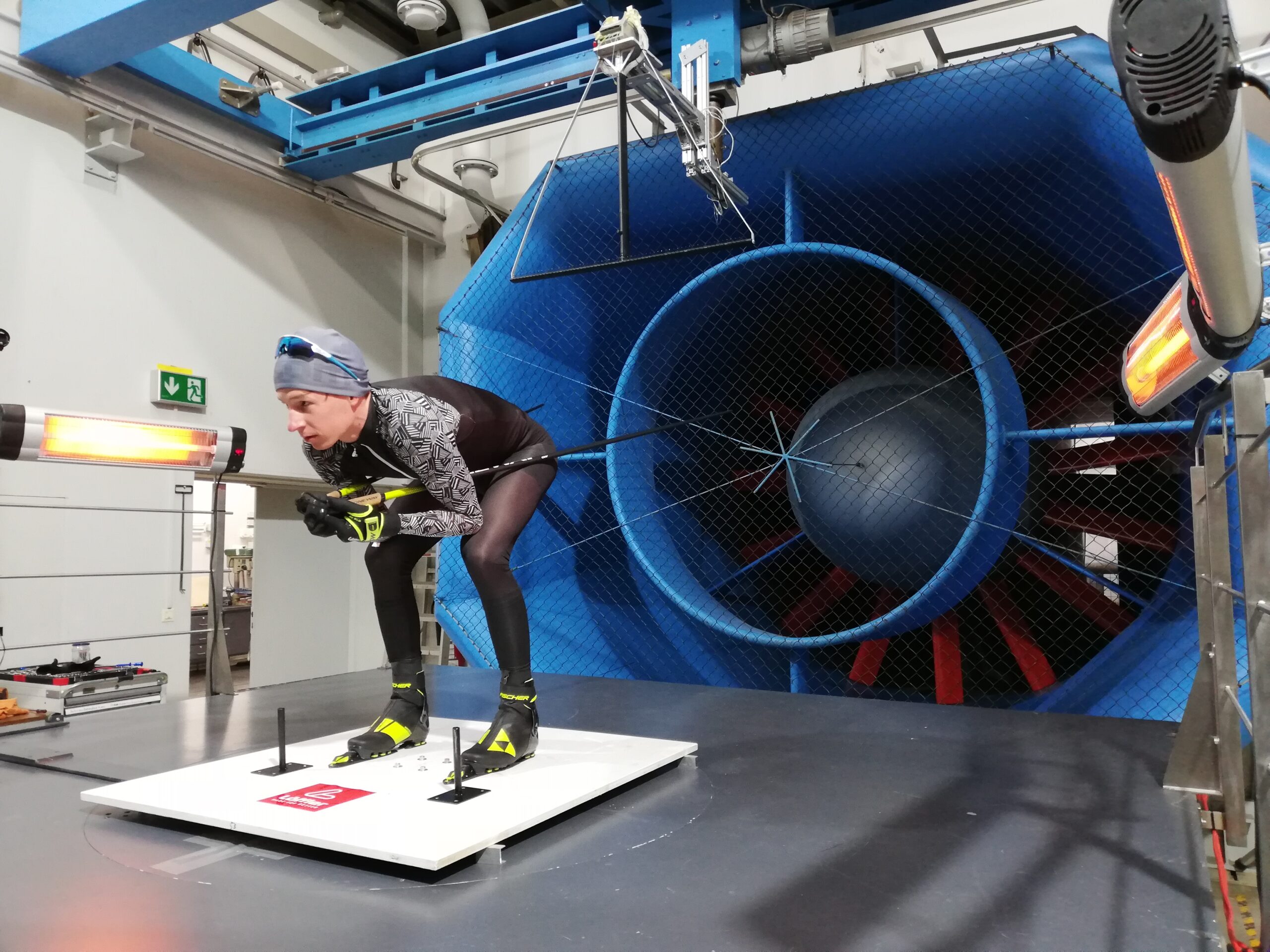

The real position of the body of the athlete is of high relevance for the overall aerodynamic situation. The Langlauf clothing tests were made with an athlete in two positions (Figure 1):

- Downhill position at 45km/h at 0° yaw only (no poles)

- Standing position at 35km/h at 0° yaw only (with poles)

Figure 1. Athlete in wind tunnel test – Standing position (Copyright University Innsbruck)

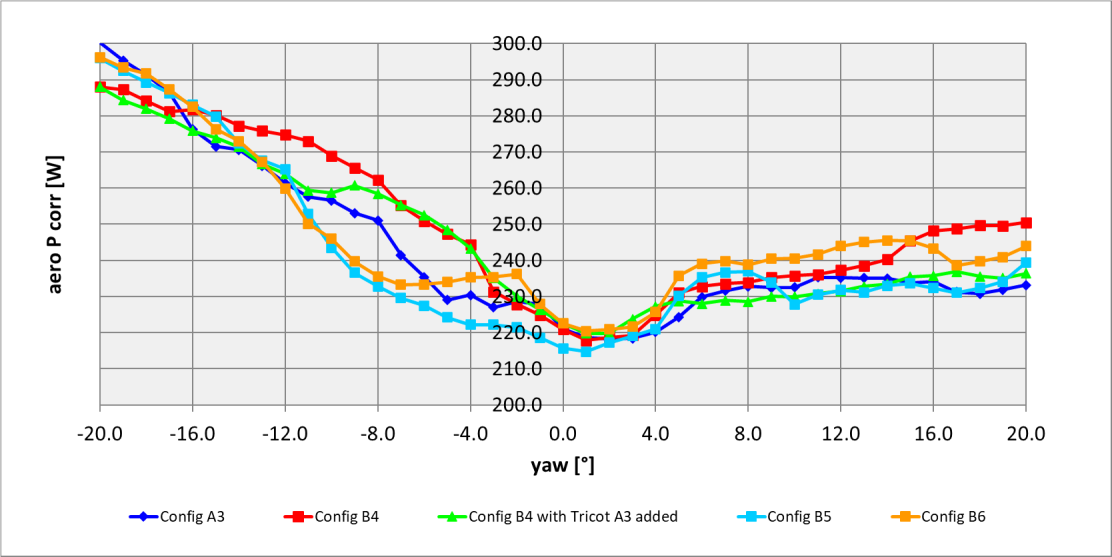

Different material configurations were tested and exhibited substantial differences in the wind tunnel analysisClothing assembly Config B5 performed best as the lowest aero drag power was measured at 45 km/h wind speed. The results gave a clear indication that more roughness is required in the shoulder region to improve the wake structure at lower speeds and most likely at other yaw angles too. The overall results were highly valuable for Löffler as a fundamental scientific basis for development of the next generation of racing suits.

Figure 2. Comparison of aeorodynamic data for different designs as function of wind speed (Copyright University Innsbruck)

Remarkably also a good accordance between the results of the small scale wind tunnel available at tccv and the full scale experiments were obtained. Thus material development will be undertaken in the more flexible small wind tunnel setup, while the final layout including the garment design will be tested in the full scale wind tunnel.

Full scale testing of the prototypes and introduction of the design into the next generation of racing suits of Loeffler is ongoing.

Multifirm project 3-020 High performance textiles

Project partner

- Research Insitute for Textile Chemistry and Textile Physics, University Innsbruck

- Löffler,Oberösterreich, AT Country

- Verein zur Förderung der Forschung und Entwicklung in der Textilwirtschaft (Textilverein), Vorarlberg, AT

The COMET-Project TCCV Project no. 860474 is funded within the context of COMET – Competence Centers for Excellent Technologies by the Austrian Ministry for Transport, Innovation and Technology (BMVIT), the Federal Ministry for Digital and Economic Affairs (BMWFW), and the federal states of Vienna, Tyrol and Vorarlberg. The programme is conducted by the Austrian Research Promotion Agency (FFG).