ENERGY GENERATION AND STORAGE ON THE BASIS OF TEXTILE-INTEGRATED ASSEMBLIES. THE OBJECTIVE WAS TO USE ENVIRONMENTAL ENERGY TO GENERATE ELECTRICITY FOR APPLICATIONS SUCH AS INTELLIGENT TEXTILES, LOW-ENERGY SENSORS, LIGHT SOURCES AND CHARGING BATTERIES.

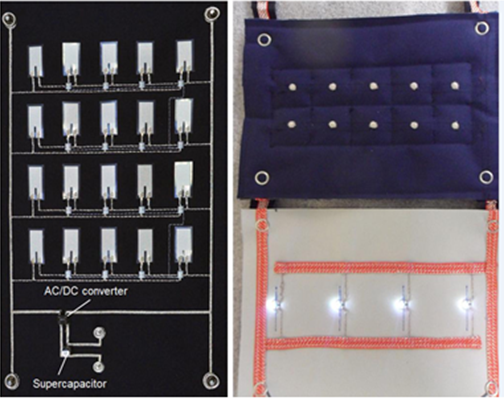

Figure 1:© TITV Greiz, Functional unit with a modular structure made up of textile-integrated energy converters, energy storage devices and energy consumers

The research project carried out served the development and further development of textile-integrated energy harvesting arrangements for the operation of electronic assemblies in smart textiles with the main application areas of medical textiles, work and protective clothing, sport and wellness, wearable electronics and telecommunications, automobiles, fiber composite technology and energy-self-sufficient sensors for various types physical measurands. Furthermore, a contribution was made to the new development of textile-based energy harvesting arrangements, in which fibers and textile surfaces made from them serve as energy converters. One objective here was to largely maintain the typical textile properties of the overall system. Weaving, knitting and braiding techniques as well as suitable coating techniques were used as the manufacturing process for the textile-based energy harvesting arrangements. The thread materials used are preferably conventional fiber materials made of polymers such as polyester and polyamide. Due to the limited thermal load capacity of these materials, the soldering of conductive threads and wires using low-melting solders had to be investigated.

Impact and effects

One of the main project results is the reliable mastery of the manufacturing and finishing process of dimensionally fixed and dimensionally accurate textile substrates for the assembly of components. This includes ensuring dimensional accuracy in the manufacturing process of the textile substrates, ensuring dimensional stability and resistance of the textile substrates to mechanical, thermal and chemical loads during further processing, securing the adhesion of the components to be mounted on the substrates and the resistance of the entire energy harvesting arrangement in use. The results were presented using a unit consisting of textile-integrated energy-converting assemblies (solar cells, piezo transducers, thermal generators), energy stores (accumulators) and consumers (light-emitting diodes). The modular structure enables adaptation to a wide range of applications. The production process consists of equipping with energy converters, for example solar cells, followed by a lamination process in which the electrical contacts and connections to the textile carrier are made. An electrically conductive adhesive fleece, the so-called e-web, is of particular importance. This material developed at TITV Greiz ensures electrical contact and, at the same time, a firm connection of electrical components and supply lines. The process for manufacturing the textile-integrated assemblies (patent pending) can be carried out cost-effectively using textile carrier materials and standard electrical components continuously on moving material webs and is characterized by only a few automatable work steps. Using typical textile connection elements such as push buttons or Velcro fasteners, the assemblies for energy generation and storage can be linked to function carriers, for example textiles equipped with light emitting diodes, to form larger units.

Multifirm project 2-010 Sensortextiles – adaptive textiles

Project partner

The COMET-Project TCCV Project no. 860474 is funded within the context of COMET – Competence Centers for Excellent Technologies by the Austrian Ministry for Transport, Innovation and Technology (BMVIT), the Federal Ministry for Digital and Economic Affairs (BMWFW), and the federal states of Vienna, Tyrol and Vorarlberg. The programme is conducted by the Austrian Research Promotion Agency (FFG).