Piezoresistive active floor mat consists of 256 sensors can detect the human stepping position, activity status on the floor.

Due to the gravity of the nature, all actions involved with human interact with the floor surface. Human body as well other objects like chair, tables, bed etc. need to be touched on the ground. Therefore, the interaction of such object with the floor is important to measure toward the smart building and smart home today. Hence, the floor is considered as one of our most frequently interactive interfaces that can be implemented with embedded sensors to extract abundant sensory information without the mostly used video-taken concerns due to the privacy issues. However, the floor sensor technology developed today are normally in a small scale due to the high implementation cost, large power consumption, and complicated device configuration etc.. Therefore, the goal of this project is to produce a piezoresistive smart-textile based floor monitoring mat, which can be low-cost and easily fabricated industrially available machines and use for the detection of the human stepping position, activity status, and identity information by scanning them based on its load or weight.

Manufacturing principle of Smart-textile ActiveFloormat

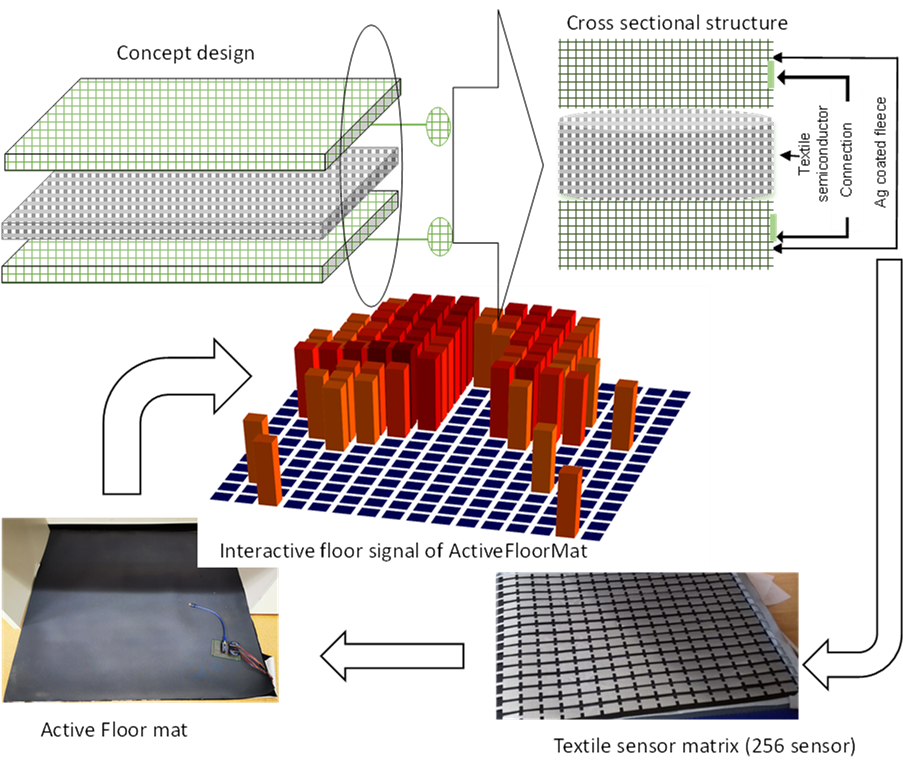

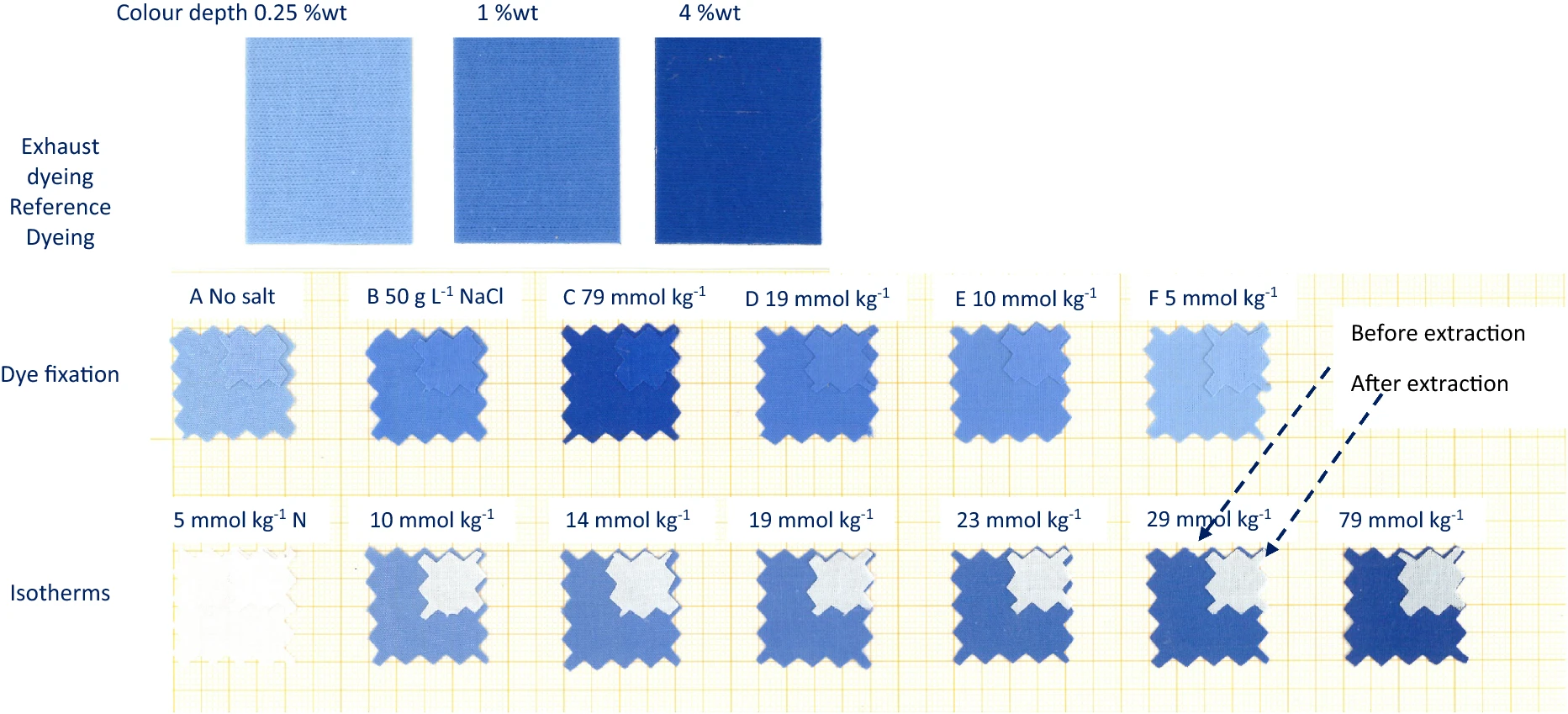

The piezoresistive sensor technology uses mainly with three-layer structure. The conductive top and bottom layers enclose a pressure-receptive middle layer that consists of a semi-conductive material. Where, the properties of the semiconductor material and uniformity of the resistive response against pressure was ensured by a homogenous plasma assisted conductive coating of textile. Thus, the ppressure sensitive semiconductor textile was designed and structured for floor sensor mat application. Sandwich like structure was made by two conductors’ silver coated fleece and the previously developed pressure sensitive semiconductor textile in between as can be seen in Fig. 2. Both (top and bottom) electrodes were placed in a way so that the conductive surface face towards the pressure sensitive semi conductive textile. Sandwich form was generated by a temperature/pressure sensitive adhesive fleeces of about 40 g/m2 around the edges between top and bottom nonwoven electrode, so that they are directly opposite each other, on the opposed surfaces of the semiconductor. Lamination condition of the sensor was at 120°C and with pressure 40N using for 45 Second.

Results and discussion

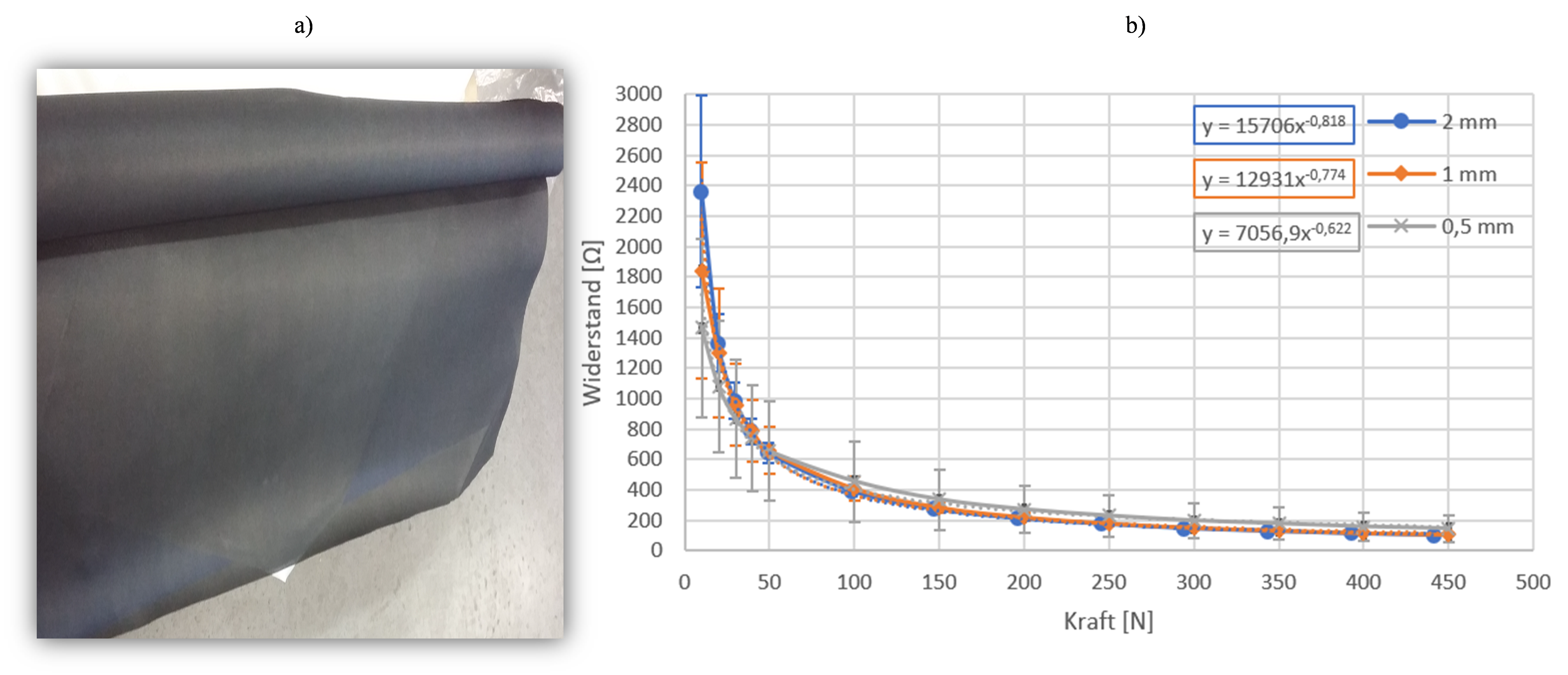

As can be seen in Figure 1 the change of electrical resistance in semi-conductive textile occurs when changing the distance between conductors by the applied forces, while uses in piezoresistive sensors. It is therefore bendable, flexible, breathable, washbale and ideal for piezoresistive floor sensor mat application. As presented in Fig. 1. the resistance of the pressure sensitive conductive textile for 3 different thickness have been measured with an applied load from 0 up to 450 N. As can be seen the resistant value with an empty load is around 3000 W, which is decreased gradually by increasing the load on the mat surface and the lowest resistant (180 W) value was observed at a maximum load of about 450 N. However, the Fig. 2 shows multiple sensors matrix, where each column of the bottom electrode is interconnected, that cooperate with each other to form multiple pairs of opposed contacts. Finally, connecting point of the sensor mat were built separately with copper wire and used for the electronic connection for the demonstration.

Figure 1. Industrial scaleup of piezoresistive textile (left) and their variation of resistant value over applied load (right) (Copyright V-trion)

Thus, the ActiveFloorMat has been developed with a matrix of 256 piezoresistive sensor for a dimension of 100×100 cm2 mat surface as can be depicted in Figure 2.

Figure 2. Manufacturing mechanism of smart-textile piezoresistive ActivfloorMat (Copyright V-trion)

The resistant variation over 2000 W of the sensor mat by the pressure within 0 to 450 N provide an opportunity to detect and scan a wide range of object. Which can be installed in smart-home or building’s floor as the functional interface for intelligent automation, healthcare, and security and monitor human walking, including indoor position, activity status, individual identity, etc.

Multifirm project 2-020 Smart home

Project partner

- V-trion, Vorarlberg, AT

- Kapsch AG, Wien, AT

- Wirtschaftskammer Vorarlberg – Berufszweig Stickereiwirtschaft, Vorarlberg, AT

The COMET-Project TCCV Project no. 860474 is funded within the context of COMET – Competence Centers for Excellent Technologies by the Austrian Ministry for Transport, Innovation and Technology (BMVIT), the Federal Ministry for Digital and Economic Affairs (BMWFW), and the federal states of Vienna, Tyrol and Vorarlberg. The programme is conducted by the Austrian Research Promotion Agency (FFG).