ANODIC COATING OF FISH-FARMING NETS AS NON-TOXIC COATING FOR ANTIFOULING PROTECTION

To prevent attack of predator fish to fish farms coarse meshed stainless steel nets are used. However, if in contact with an aquatic environment, steel tends to suffer from biological fouling, which renders its use limited. Thus these steel nets have to be cleaned regularly, which requires considerable manpower. To prevent stainless steel from fouling, different coating and treatment methods have been developed, often incorporated biocides (e.g. copper oxides) are part of such rather toxic coatings. Thus such coatings are not applicable for fish breeding. An alternative coating should be non-toxic however should develop a lasting effect against biological fouling.

Fundamental electrochemical investigations

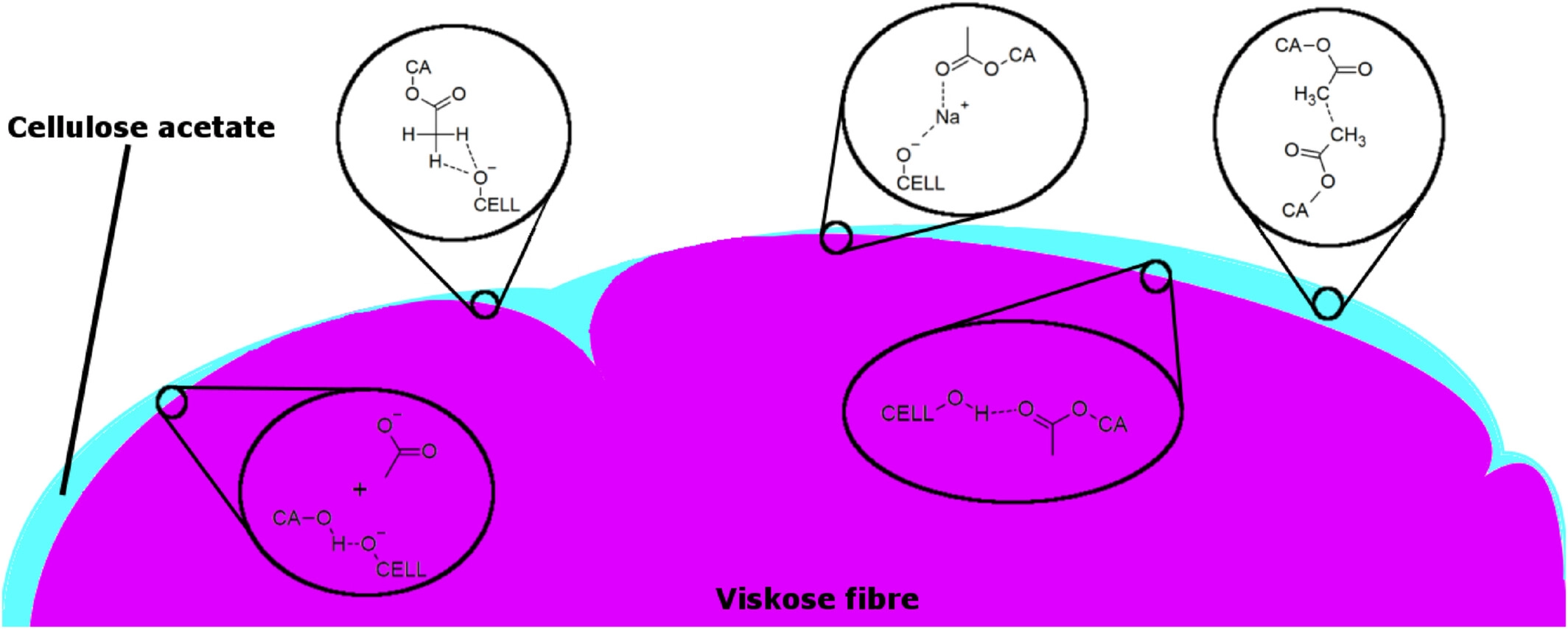

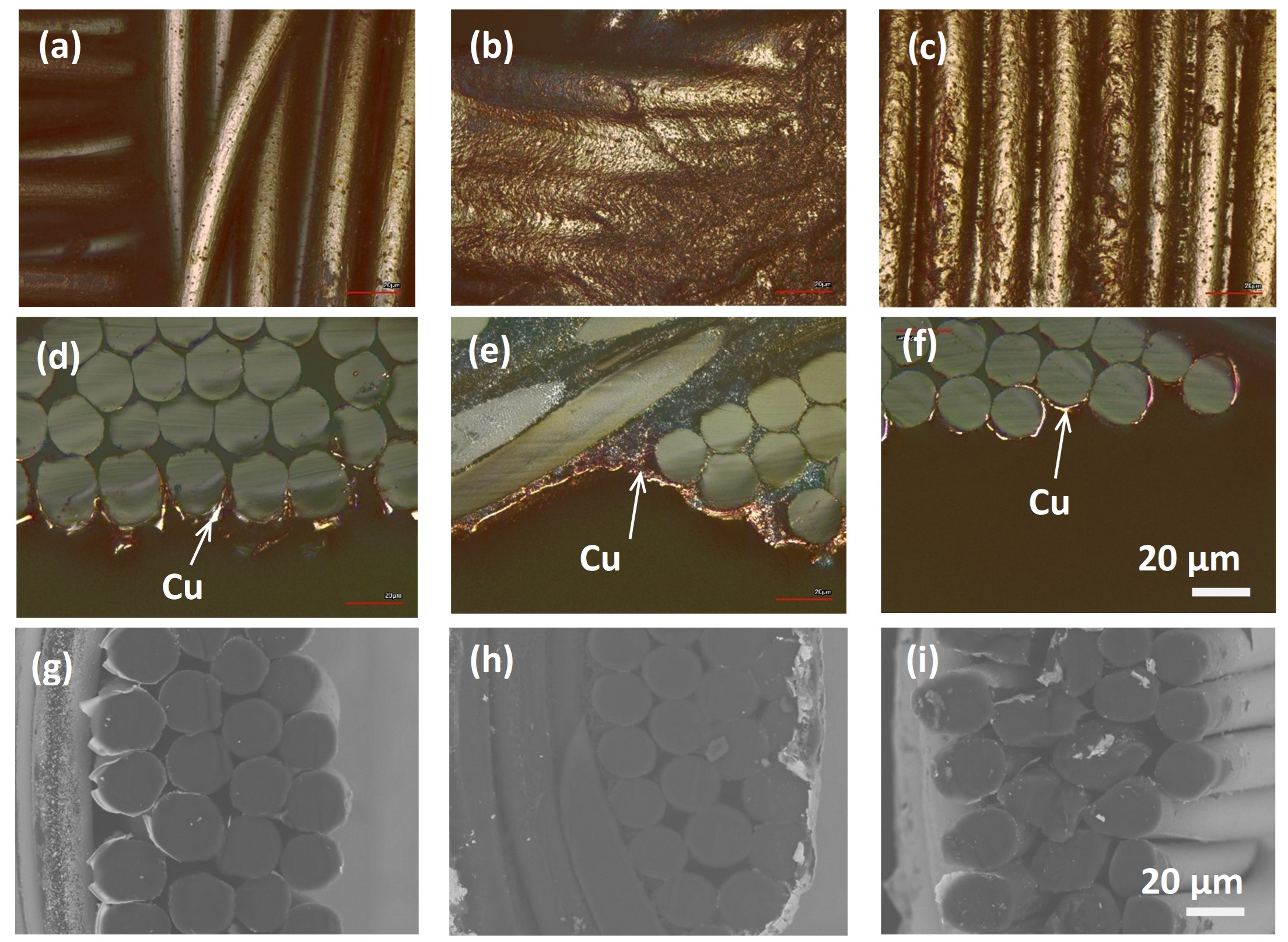

Anodic coating of dopamin leads to surface coatings of polydopamine. In laboratory experiments it could be demonstrated, that anodic coating of the electrically conductive stainless steel nets can be achieved with formation of an insoluble polydopamine layer. Fundamental studies with cyclic voltammetry and galvanostatic deposition were performed to elaborate the chemical basis to understand the chemistry behind.1,2

(1) Schindler, S.; Aguiló-Aguayo, N.; Dornbierer, U.; Bechtold, T. Anodic Coating of 1.4622 Stainless Steel with Polydopamine by Repetitive Cyclic Voltammetry and Galvanostatic Deposition. Ind. Eng. Chem. Res. 2020, 59 (1). https://doi.org/10.1021/acs.iecr.9b05603.

(2) Schindler, S.; Bechtold, T. Mechanistic Insights into the Electrochemical Oxidation of Dopamine by Cyclic Voltammetry. J. Electroanal. Chem. 2019, 836. https://doi.org/10.1016/j.jelechem.2019.01.069.

Figure 1: Representative example for growth on a test steel plate. (Copyright Geobrugg AG)

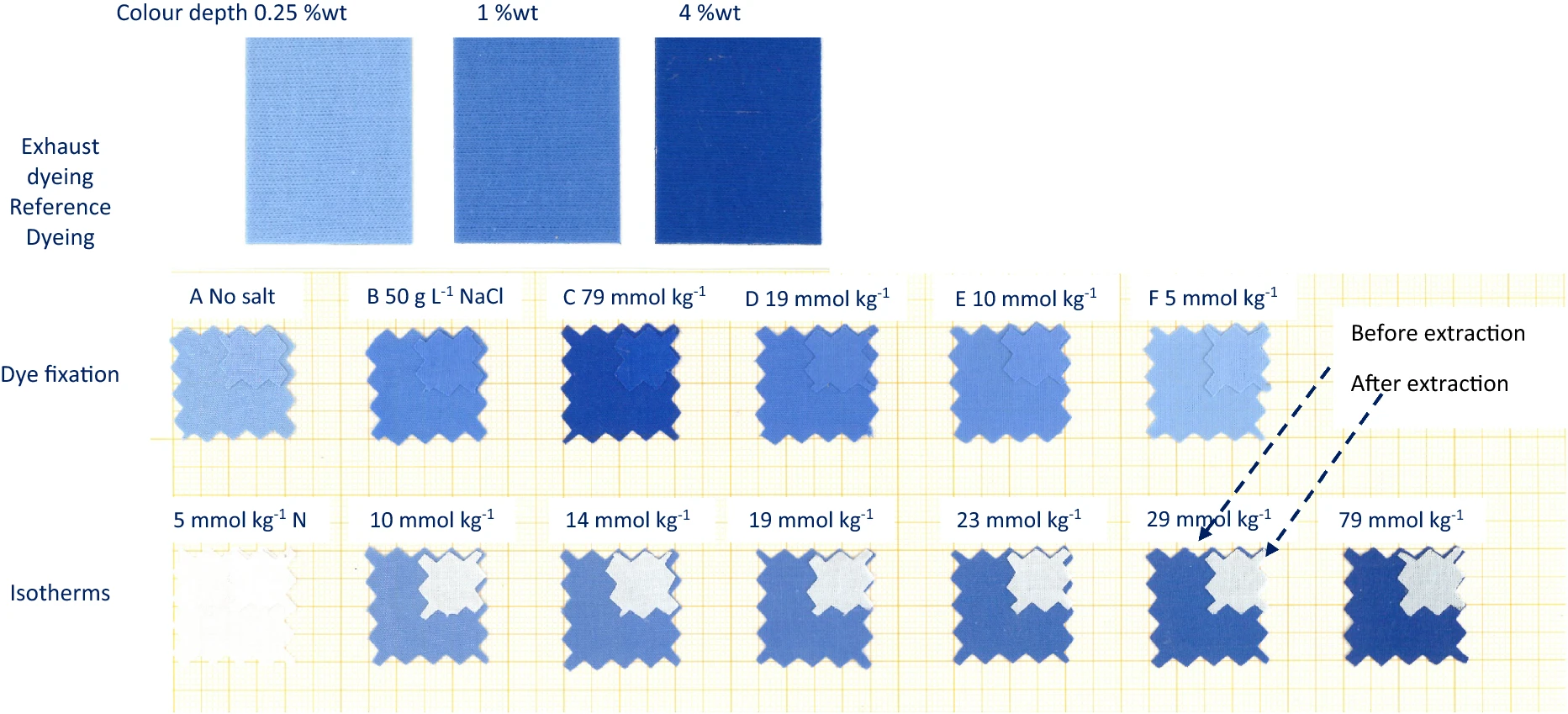

Based on the results from fundamental studies a scale-up was performed and in a first approach smaller metal plates were coated with the anodic polydopamin deposition.

Remarkably these demonstrators exhibited promising antifouling properties in a first on-site test in a Chilean fish farm.

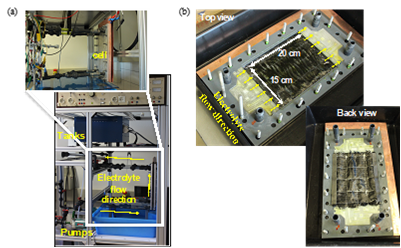

Further development and Scale-up

Based on the promising results from the small plate coatings, the anodic coating was transferred to larger scale steel nets (ca. 1 m2). The coated nets then were tested in a Chilean fish farm, again with very promising results. A number of different coatings had been tested in this series. Based on an evaluation of these results selected coatings selected for another optimisation step, which is now in execution in Chile.

Advantages of the technology are:

- Only non-toxic substances are processed

- For coatings bio-based material is used

- The technology of the concept is rather sophisticated, however the equipment is simple, thus a transfer into production scale will not require extensive investment for equipment.

Multifirm project 2-030 Smart and safe work

Project partner

- Research Institute for Textile Chemistry and Textile Physics, University Innsbruck

- Geobrugg AG, CH

- Verein zur Förderung der Forschung und Entwicklung in der Textilwirtschaft (Textilverein), Vorarlberg, AT

Project coordination (Story)

Univ.Prof. Dr. Thomas Bechtold

Research Institute for Textile Chemistry and Textile Physics; University Innsbruck

Hoechsterstrasse 73

6850 Dornbirn

T +43 (0) 512 507 55003

The COMET-Project TCCV Project no. 860474 is funded within the context of COMET – Competence Centers for Excellent Technologies by the Austrian Ministry for Transport, Innovation and Technology (BMVIT), the Federal Ministry for Digital and Economic Affairs (BMWFW), and the federal states of Vienna, Tyrol and Vorarlberg. The programme is conducted by the Austrian Research Promotion Agency (FFG).